Understanding Rapid Prototyping in China

Rapid prototyping has revolutionized the way businesses approach product development, particularly within the realm of metal fabrication. In recent years, China has emerged as a leader in this field, leveraging its advanced technologies, skilled workforce, and competitive pricing. In this comprehensive article, we will explore the ins and outs of rapid prototyping in China, showcasing its benefits, processes, and how it can be a game-changer for your business.

The Essence of Rapid Prototyping

At its core, rapid prototyping is a categorical approach to developing prototypes quickly and efficiently. This technique allows designers and engineers to produce models that can be tested and refined before the final product is launched. The speed of this process not only accelerates the design phase but also significantly reduces costs and minimizes risks during the product development lifecycle. By integrating rapid prototyping, companies can:

- Test design concepts swiftly.

- Receive immediate feedback from stakeholders.

- Iterate on designs with ease and precision.

The Advantages of Rapid Prototyping in China

China’s robust manufacturing ecosystem offers a variety of advantages for rapid prototyping that cannot be overlooked:

1. Cost Efficiency

One of the primary benefits of utilizing rapid prototyping services in China is the cost efficiency. With lower labor costs and a developed supply chain for raw materials, companies can save significantly on production expenses.

2. Access to Advanced Technology

China is home to some of the latest manufacturing technologies in rapid prototyping, such as:

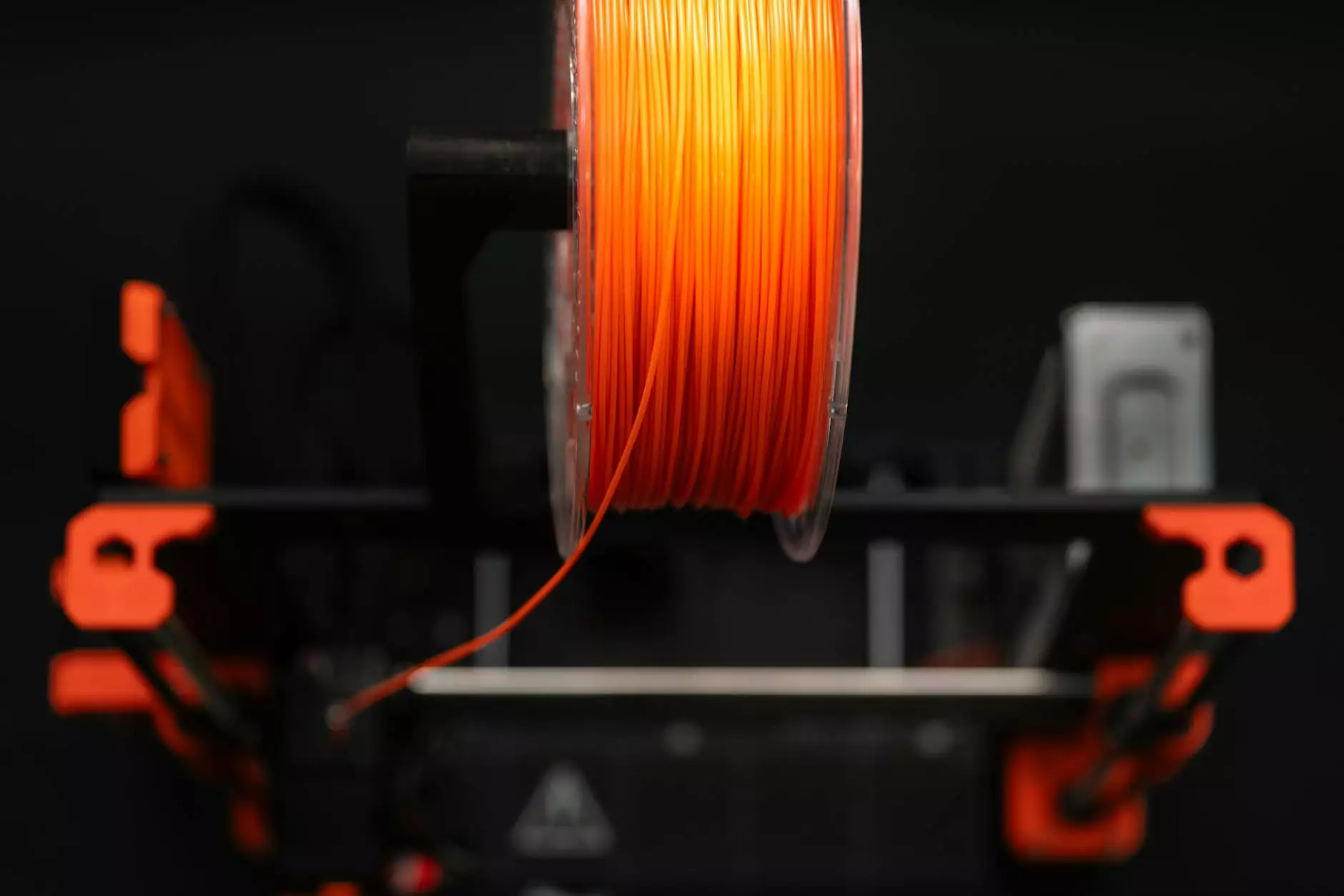

- 3D Printing: This technology allows for the creation of complex geometries that would be impossible with traditional manufacturing methods.

- CNC Machining: Computer Numerical Control (CNC) machining provides high precision and the ability to produce durable metal parts effectively.

- Injection Molding: Essential for mass-producing prototypes rapidly, this method is invaluable for creating high-quality components.

3. Rapid Turnaround Times

Companies can expect significantly faster turnaround times by sourcing rapid prototyping services in China. This speed enables designers to iterate faster, leading to quicker market entry.

4. Skilled Workforce

With a workforce that fosters both technical expertise and innovation, China's engineers and designers are well-equipped to handle cutting-edge metal fabrication tasks.

Key Processes in Rapid Prototyping

The process of rapid prototyping consists of several key steps. Here’s a detailed look at how the process works:

1. Initial Concept and Design

The journey starts with the creation of a detailed design, often using Computer-Aided Design (CAD) software. This digital representation is crucial as it outlines every aspect of the product and serves as a guide for subsequent stages.

2. Material Selection

This stage involves choosing appropriate materials. Different materials offer unique properties and capabilities, such as:

- Metal/alloy: For strength and durability.

- Plastic: For lightweight and versatility.

- Composite materials: To combine benefits of both metals and plastics.

3. Prototype Production

Once the design and materials have been finalized, the actual prototype is produced. This is where different techniques come into play, including 3D printing or CNC machining, to create the physical model that stakeholders can examine.

4. Testing and Evaluation

After the prototype is produced, it is subject to rigorous testing. This ensures that the product meets all necessary performance standards and user requirements.

5. Refinement and Finalization

Based on feedback from testing, the prototype may undergo several iterations, refining its design until it aligns perfectly with the intended purpose.

The Future of Rapid Prototyping in China

The landscape of rapid prototyping is continually evolving, with advancements that promise even greater efficiencies and innovative solutions. Looking ahead, we can anticipate:

1. Integration of Artificial Intelligence

The integration of AI technologies in the design and production processes will enable more intelligent and adaptable systems that learn from previous iterations, enhancing speed and quality.

2. Sustainable Practices

In response to global calls for sustainability, future rapid prototyping practices will likely focus on eco-friendly materials and processes. This shift will not only reduce waste but also align with the increasing demand for sustainable products.

3. Enhanced Collaboration Tools

As businesses become more connected, collaborative tools that streamline communication between designers, engineers, and manufacturers are on the rise. This increased collaboration will facilitate smoother workflows and faster decision-making processes.

How to Choose the Right Rapid Prototyping Service in China

When looking for a partner for rapid prototyping in China, consider the following tips to ensure you make the best choice:

1. Evaluate Their Experience

Examine the company's portfolio and previous projects in the metal fabrication sector. A well-established firm like DeepMould can provide insights based on their extensive experience.

2. Compare Pricing Models

While cost is important, consider the overall value provided. Ensure that the pricing reflects the quality of service you receive.

3. Request Samples

Before committing, ask for samples of previous work. This allows you to gauge the quality of the prototypes produced by the service provider.

4. Check Client Testimonials

Look for reviews and testimonials from other clients to understand their experiences. A reputable company should have positive feedback, showcasing their reliability and quality service.

Conclusion

In conclusion, rapid prototyping in China is not just about speed; it's a comprehensive solution that provides businesses with the opportunity to innovate, save costs, and bring products to market faster than ever. With its advantages in technology, skilled workforce, and cost-effectiveness, it's clear why many companies are turning to China for their prototyping needs.

Embracing this method can lead to significant improvements in your product development process, ultimately driving success in an increasingly competitive marketplace.

rapid prototyping china